When running a food service establishment, one of the best things you can do to benefit your business is keep your facility clean. Your customers want to eat in a restaurant that is clean and sanitary as a dirty or poorly maintained restaurant is off putting and may make your guests feel unsafe. Issues with the plumbing system can lead to several problems that can make your establishment unsafe and force you to shut down. In our last blog, we covered what to do if there is a backup in your plumbing system. In part 2, we will discuss what to do if there is a problem with your electrical pumps or a foul odor coming from the plumbing system.

Electrical pumps are a necessary part of the plumbing system in a food service establishment because they help prevent flooding and sewage backups by ensuring that all drainage leaves the property. If there is a problem with this equipment, flooding may occur on your property and force you to shut down.

You should also be concerned about foul odors as this can instantly turn away your guests. Foul odors in food establishments generally occur due to a problem in your floor drains or plumbing stacks. These odors are unpleasant and will instantly cause your guests to leave, resulting in lost revenue. Even if your restaurant is not dirty, the odor will make it seem unsanitary to your guests. If you are having an issue with foul odors, it is important to know how to remove these odors and avoid loss of business.

In this guide, we will discuss the different sources that may cause unpleasant odors in your food service establishment and what you can do to eliminate these odors. We will also cover how to check your electrical equipment of your plumbing system if there is a problem.

Eliminating Foul Odors

Foul odors in your establishment will give a terrible impression to your guests and make them think that your restaurant is unsanitary. If there is an unpleasant odor in your establishment, it is likely from one of two sources: the floor drains or the plumbing stacks. The following tips will help you address odors from both sources:

Floor Drains

The first thing you should do if there is a foul odor in your establishment is check the floor drains that do not have water flowing through them consistently. Floor drains that do not see a consistent flow of water may have water sitting in the p-trap that will eventually evaporate. When this happens, sewer gas can enter your establishment. The water in the p-traps is most likely to evaporate in the winter due to the heating and in the summer due to the air conditioning.

You can eliminate the sewer gas odor from the floor drain by doing the following:

- Check the floor drains for visible water.

- If you do not see water in the drain, pour vegetable oil in the drain.

- The vegetable oil will not evaporate but allow the water to drain underneath it because the oil is lighter than water.

- The vegetable oil will prevent the sewer gas from coming into your establishment and it will not solidify and clog your drains.

Plumbing Stacks

If the odor is not sewer gas coming from the floor drains, then the odor is most likely coming from the plumbing stacks. Plumbing stacks are attached to the plumbing vents in your plumbing system and they allow sewer gas to escape the building through the roof. The plumbing stacks on your roof need to be tall enough to allow the sewer gas to escape or the air-intake units will suck the gas back into the building.

If the plumbing stacks are too short, talk to a plumber or your contractor to address the problem. If the odor continues after the problem is addressed, a smoke test can be done to identify the source of the odor. A plumber or rodder can do this test.

Electrical Pumps

There are several types of electrical pumps within your plumbing system that help eliminate water and sewage from the property. It is important to check the following electrical pumps to identify and take care of any problems.

Ejector Pumps

Ejector pumps move water from lower levels to higher levels which is why they are commonly found in basements. If there is a problem with an ejector pump, it is most likely because a fuse was blown, or a cord became unplugged. Make sure you stop using everything on the level where the pump is located and take these steps to identify the problem:

- Make sure the plug for the ejector pump is plugged in and that it is receiving power.

- If the pump is plugged in, check the circuit breaker. The ejector pump can blow a circuit after extended use. If the pump does not come back on after resetting the circuit, you need to have a repairman or plumber check out the pump.

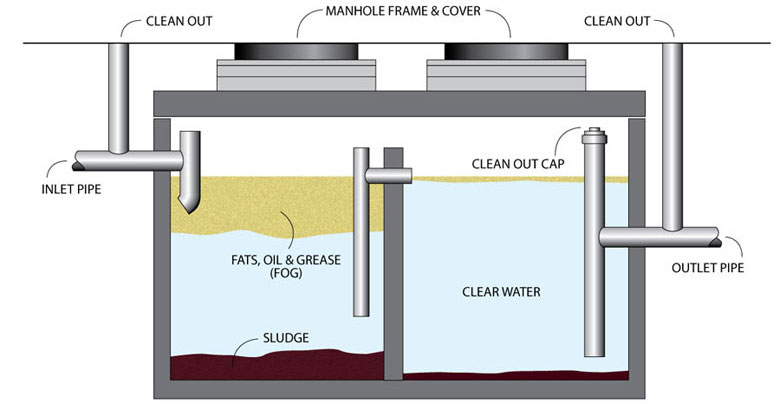

You can help prevent problems with the ejector pump by having the grease traps in the basement or lower level cleaned out every 4 weeks. If the grease and oil is allowed to build up in the grease trap, the pump can burn out from becoming overloaded. Call a professional like Mahoney Environmental to provide grease trap cleaning.

Lift Stations

Lift stations allow sewage to leave a building and they are typically located outside. Individual establishments may have their own lift stations and they can also be used in malls to handle eliminating sewage from multiple restaurants. If the lift stations stop working, sewage can back up into the building.

Take the following steps if the lift station stops working:

- Make sure there is power going to the pump.

- Call the company that provides repairs and preventative maintenance for the lift station if there is no power going to it.

- You should also call the company that cleans your grease traps because they may need to remove grease and oil from the lift station.

You can help prevent problems with the lift station by having the grease traps in your establishment cleaned regularly. If the grease traps are not cleaned out, the built-up grease, fats, and oils can get into the lift station and cause it to overload.

Sump Pumps

Sump pumps are installed in basements and lower levels to eliminate ground water from the building. They should be plugged into a float plug that is plugged into the wall. The float plug will control the pump when it needs to run and if the float plug malfunctions, you can plug the sump pump into the wall and run it manually until the float pump is fixed.

If your sump pump stops working, follow these steps:

- Make sure the sump pump is connected to the power source.

- If the power source is connected, check for a problem with the circuit.

- If the sump pump is plugged in and the circuit is fine, call a professional to inspect and repair it.

You can help prevent problems with your sump pump by providing the necessary maintenance and monitoring the pump regularly to look for any problems. You should also consider having a battery powered sump pump as a backup to prevent your establishment from flooding if there is a power outage or a problem with the sump pump.

Grease Trap Cleaning and Maintenance from Mahoney Environmental

Plumbing issues that lead to flooding or foul odors in your establishment are bad for business and can affect your bottom line. Make sure you regularly check plumbing equipment and drains for any issues and provide the proper maintenance to avoid malfunctions in the equipment or situations that lead to foul odors.

One of the best ways to prevent plumbing issues in your food service establishment is to work with a professional that can provide grease trap cleaning and maintenance. Our professionals at Mahoney Environmental can work with you to provide regularly scheduled maintenance and cleaning for your grease traps.

You can reach us at (800) 892-9392 to learn more or to schedule grease trap cleaning and maintenance services with our professionals at Mahoney Environmental.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392