How Grease Traps Work

Grease traps are a very important feature of commercial kitchens because they prevent fats, oils, and grease (FOG) from washing down the drain and into the municipal sewer system. It is so important to keep FOG out of the sewer system because these materials solidify in the water, which can clog the plumbing system and sewer lines. Blockages within the system can cause untreated wastewater to discharge into the street and surrounding natural environment and result in overflows within commercial kitchens. Clogs caused by FOG are the leading cause of sanitary sewer overflows.

All commercial kitchens must have grease traps to help protect the sewer system from damage that can lead to overflows and pollution of the natural environment and waterways. Failure to effectively prevent FOG from being washed down the drain not only leads to costly damage but also fines and other penalties for foodservice establishments. Most local governments require restaurants to have grease traps, and they need to be cleaned out and maintained to effectively filter FOG from the wastewater so these materials do not end up in the sewer.

In this guide, we explain what grease traps are and how they work, as well as the importance of grease trap cleaning and maintenance to keep them functional.

What is a Grease Trap?

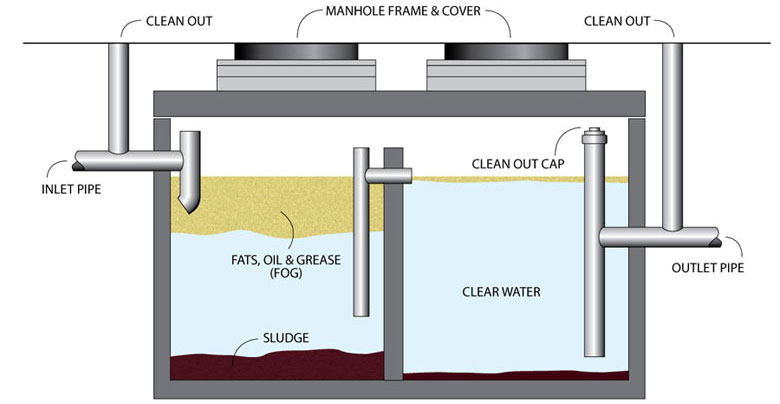

A grease trap is a container that captures FOG from the wastewater before it reaches the municipal sewer system. The traps are typically located under the floor of a commercial kitchen and the pipes from sinks, dishwashers, and floor drains run into the traps so all wastewater is filtered. The traps effectively separate and collect the FOG, as well as sugar and other solids, from the wastewater and allow the filtered water to pass through into the sewer system.

Grease traps consist of the following parts that help remove the FOG from the wastewater before it enters the sewer:

- Inlet pipe: The inlet pipe is the pipe that brings the wastewater into the trap.

- Inlet T fitting: This part slows the flow of the water into the trap and cools the water temperature. There should be no cap on the inlet side.

- Outlet fitting and cap: The outlet fitting and cap should be about 18 inches from the base of the trap, allowing only water to flow out to the sanitary sewer.

- Baffle walls: Baffles are metal barriers that slow the flow of the water on the inlet side so the FOG can separate from the water. Their key function is to keep FOG from reaching the outlet side.

- Outlet pipe: This is the pipe that sends water that exits the trap into the sewer system.

- Manhole covers: These covers cap off each side of the trap. They should be made of solid steel, never cement.

How Do Grease Traps Work?

Grease traps work by effectively separating FOG and solids from the wastewater, trapping these materials inside while allowing the filtered water to flow out of the trap and into the sewer line. The following is the process of how the traps work:

- The wastewater from the sinks, dishwashers, floor drains, and mop sinks makes its way into the inlet pipe.

- The inlet T fitting slows the flow of the water and cools it down before it enters the inlet side of the trap. Cooling the water solidifies the FOG so it can separate from the water more easily.

- On the inlet side, the FOG separates from the water and rises to the top of the trap while solids sink to the bottom. The clean water then flows into the outlet side through a transition pipe. The inlet and outlet sides are separated by baffles that help prevent the FOG from reaching the outlet side.

- On the outlet side, the water must pass through the outlet baffle towards the outlet pipe which helps separate the remaining FOG and debris.

- The water then exits the trap through the outlet pipe and enters the sewer system.

The Importance of Cleaning the Grease Traps

The FOG and solids that are separated from the wastewater accumulate within the traps over time. It is very important to clean out the traps and remove the built-up FOG and debris to ensure that only clean water enters the sewer system. The more FOG and debris there is built up within the trap, the more likely it is for these materials to exit the outlet pipe and reach the sewer system.

Foodservice establishments must have their grease traps cleaned regularly. However, the frequency that cleaning is needed depends on the size of the grease trap and the volume of grease produced by your kitchen. The best way to determine when your grease traps should be cleaned is by using the one-fourths rule. Once the trap becomes 25% full of FOG and other materials, the risk of leaks, overflows, and FOG entering the sewer system increases. Therefore, you should clean out the grease traps either before they become 25% full, or immediately once they reach this capacity.

The best strategy is to set up regular grease trap cleanings with a professional like Mahoney Environmental to ensure that your traps are cleaned before they become 25% full of FOG and other materials. Professionals will come to your establishment at scheduled intervals with the proper equipment to effectively remove built-up FOG and debris from the traps. Regular cleanings help keep your grease traps functional, avoid damage and clogs within the traps, and ensure that your establishment is compliant with municipal codes which protects your business from fines and other penalties.

Grease Trap Cleaning from Mahoney Environmental

Grease traps are a necessary feature of commercial kitchens to protect the sewer system from damage and prevent pollution of the natural environment and waterways. When properly maintained, grease traps are a highly effective method for separating and trapping FOG while allowing clean water to flow into the sewer system. However, if your traps become full, clogged, or damaged, this could result in foul odors, overflows, contamination of the wastewater, and expensive remediation services.

At Mahoney Environmental, we offer grease trap cleaning and maintenance services to effectively clean the built-up FOG from the traps and ensure that your traps are functional and in good repair. We have been a leader in grease trap cleaning and maintenance for more than 70 years and we can tailor our services to the specific needs of your business.

You can expect timely grease trap cleaning based on your schedule and we will check the traps to identify and address necessary repairs and maintenance. We also provide a full inspection report of your traps on each visit and the documented history we create with our inspection reports helps us anticipate needed maintenance which prevents costly damage. Working with Mahoney for professional grease trap cleaning ensures that your traps are always functional and keeps your business in compliance with municipal regulations.

You can call Mahoney Environmental at (800) 892-9392 for more about our grease trap cleaning services.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392