Have you ever wondered what happens to your used cooking oil (UCO) after Mahoney Environmental collects it from your restaurant? The journey your UCO takes is not only fascinating but also highlights the critical role it plays in sustainable energy production. Let’s dive into the detailed process and see how Mahoney Environmental transforms your used cooking oil into a valuable resource for the production of renewable diesel and sustainable aviation fuel (SAF).

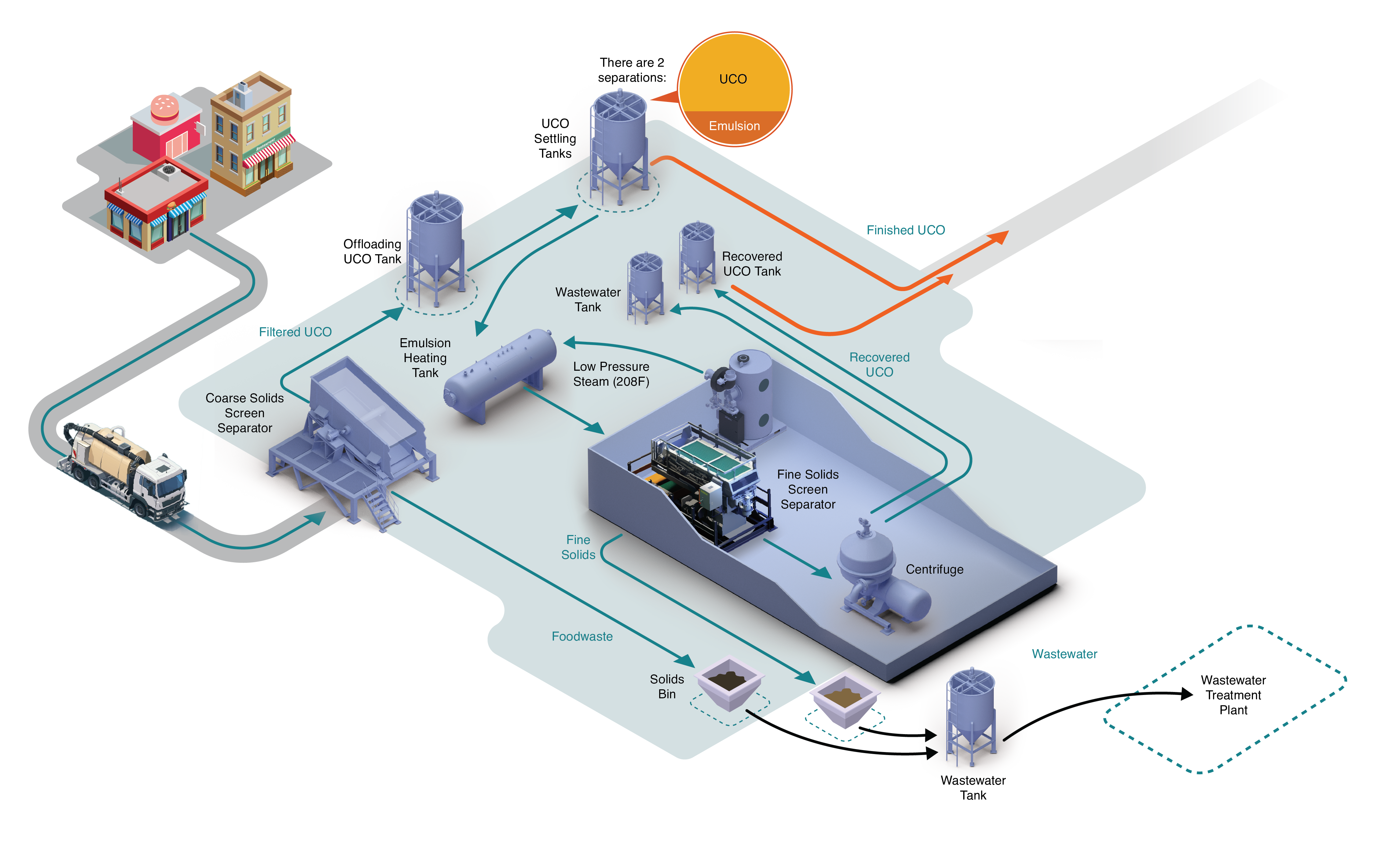

Step 1: Transportation to a UCO Processing Plant

Once Mahoney Environmental collects your used cooking oil, it’s transported to one of our locations for processing. At the facility, raw UCO is unloaded from trucks into a receiving pit, the starting point of its transformation journey.

Step 2: Heating and Initial Separation

In the receiving pit, the UCO is carefully heated to ensure it drains safely and efficiently through a screen at the bottom. During this heating process, an auger conveys solid materials such as plastic, glass, and metal out of the mixture. These solids are separated and sent to waste disposal.

Step 3: Rota-Strainer Filtration

Next, the liquid UCO is pumped to a rota-strainer, where smaller solids are filtered out. Materials like glass and gravel are removed and disposed of, leaving behind a cleaner liquid that is then directed to a settling tank for further processing.

Step 4: Settling Tank Separation

In the settling tank, the UCO is heated and left to sit until the UCO separates. This critical process allows the UCO to separate into three distinct layers:

- Water: Drained off and sent to the wastewater operation for treatment in an anaerobic digester.

- Emulsion: A combination of water, oil, and solids that require additional processing.

- Oil: The finished UCO is checked for free fatty acid levels and solids percentage, then sent to storage for shipment.

The emulsion that can’t be separated by gravity is sent to the evaporator for processing.

Step 5: Evaporation Process

In the evaporator, the emulsion is recirculated and heated under vacuum conditions. This process evaporates the water, leaving the solids and oil behind, and the vaporized water is directed to an air condenser. Here, fans cool the vapor back into liquid water, which is sent to wastewater processing. Non-condensable vapors are incinerated in boilers.

Step 6: Centrifuge Separation

The remaining oil and solids are sent to a centrifuge to be mechanically separated. Solids, primarily flour, and starch from frying processes, are repurposed as low-protein animal feed. The oil is stored and periodically checked for quality and solids content.

Step 7: Quality Assurance and Storage

The finished UCO from the processing plant and outside sources is inspected for free fatty acid levels and solids percentage before being sent for storage. At this stage, batches of oil are blended according to customer specifications. A sample from each batch is sent to a lab for rigorous testing, ensuring it meets standards for pesticides, insecticides, and PCB levels.

Step 8: Conversion to Renewable Fuel

Nearly 100% of the used cooking oil collected by Mahoney Environmental is sold as a feedstock for renewable fuel production, including renewable diesel and SAF. This makes your restaurant’s used cooking oil a critical part of the global movement toward cleaner, renewable energy sources.

Why Recycling UCO Matters

By recycling used cooking oil, restaurants contribute to reducing waste, lowering carbon emissions, and supporting the production of renewable fuels. Mahoney Environmental ensures that every drop of UCO is processed responsibly, emphasizing environmental stewardship and innovation. The next time Mahoney Environmental collects your used cooking oil, know that you are playing an essential role in a larger sustainability effort. From careful filtration and processing to its final transformation into renewable fuel, your UCO’s journey is a remarkable example of how waste can be turned into a valuable resource.

Mahoney Environmental offers a complete range of services related to used cooking oil management and storage. Our team provides effective grease trap cleaning and maintenance to keep fats, oil, and grease from being washed down the drain. We can also design and install used cooking oil disposal systems tailored to your restaurant’s unique requirements. These systems include equipment such as bulk storage containers and portable filter machines to ensure the safe handling and disposal of used cooking oil.

Restaurants large and small across the U.S. choose us for their used cooking oil recycling needs. Contact Mahoney at 800-892-9392 to learn more about our programs.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392