The Short Answer: Yes, cooking oil does expire.

Unopened cooking oil typically lasts one to two years when stored properly at room temperature, but once opened or used in commercial fryers, degradation accelerates significantly due to heat, oxygen exposure, and food contamination. For foodservice operations, using expired or degraded oil affects food quality, increases safety risks, and drives up operational costs through more frequent oil replacement and potential equipment damage.

Understanding how cooking oil degrades, and recognizing the signs of spoilage, helps foodservice operators maintain consistent food quality while managing costs. This guide covers shelf life expectations for common oil types, indicators that oil has gone bad, and best practices for storage, maintenance, and proper disposal.

Understanding Cooking Oil Shelf Life

Cooking oil does not spoil like dairy or meat. Instead, it undergoes an oxidation process that gradually causes rancidity over time. The expiration date printed on an unopened bottle indicates peak quality rather than a hard safety cutoff. However, rancid oil develops harmful compounds and free radicals that affect both food quality and, with prolonged consumption, may contribute to long-term health concerns such as heart disease.

Different oils contain varying levels of unsaturated fats and polyunsaturated fats, which directly affect how quickly they degrade. Oils with more double bonds in their fatty acid chains oxidize faster and have shorter shelf lives.

Shelf life by oil type (unopened, proper storage):

- Extra virgin olive oil: 18–24 months. Extra virgin olive oil degrades faster than refined olive oil due to its higher fatty acids content and lack of processing.

- Vegetable oil: 1–2 years

- Canola oil: 1–2 years

- Coconut oil: 2–3 years. Coconut oil’s higher saturated fat content makes it more stable against oxidation.

- Sunflower oil: 1–2 years

- Soybean oil: approximately 1 year

- Corn oil: 1–2 years

- Walnut oil: 6–12 months. High polyunsaturated fat content makes walnut oil particularly vulnerable to oxidation.

The distinction between unopened and opened oil is significant. An unopened bottle stored in a dark place maintains quality far longer than opened oil exposed to air. Once opened, oxygen exposure begins the degradation process immediately. Frying oil in commercial kitchens degrades even more rapidly due to repeated high-temperature exposure—often within days of active use rather than months.

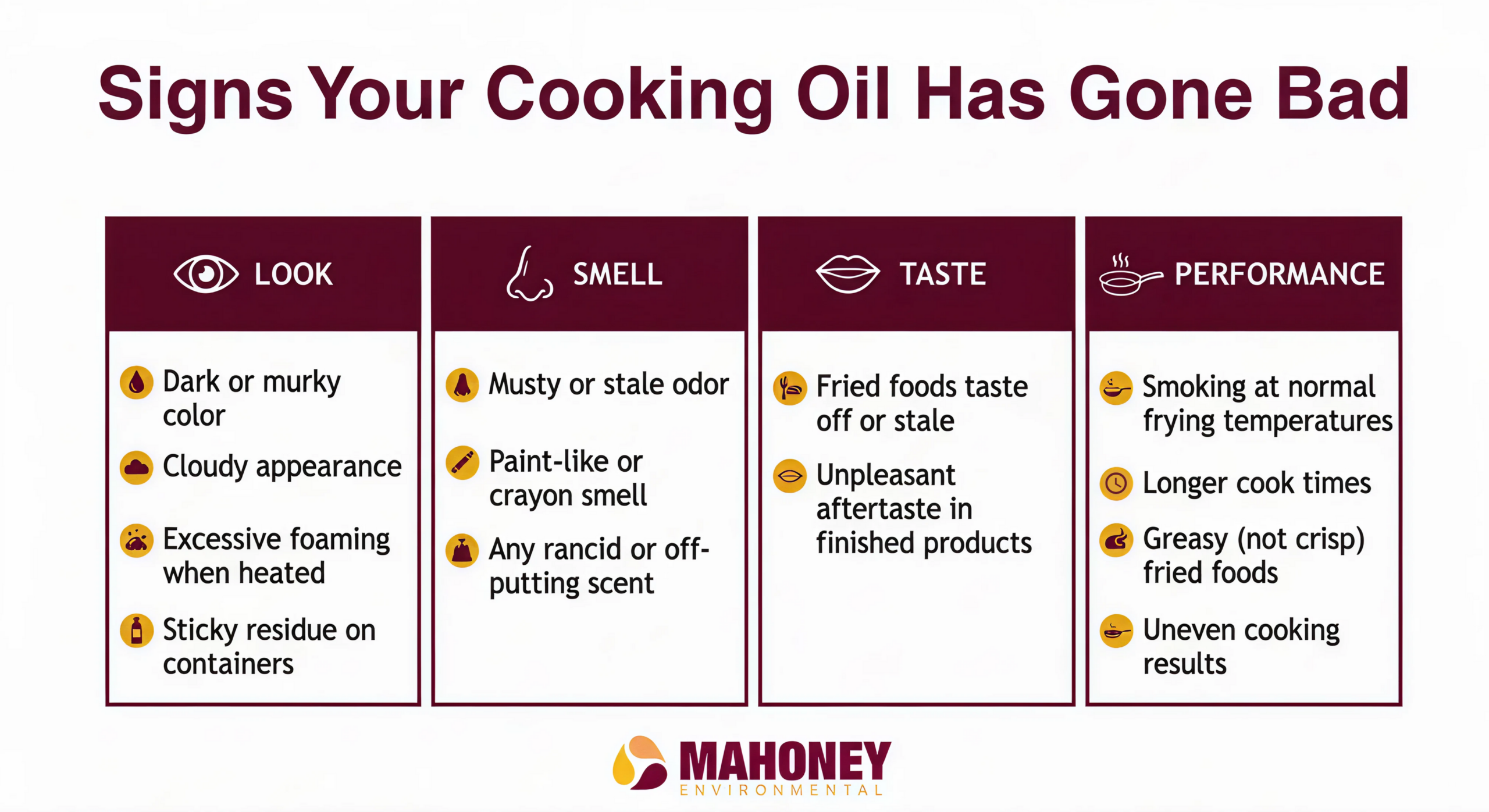

Signs Your Cooking Oil Has Gone Bad

Recognizing the signs of spoilage prevents serving substandard food and helps operators time oil changes appropriately.

Visual Indicators

Visual changes offer the first warning signs that oil has degraded:

- Darkening color beyond normal use changes

- Cloudy or murky appearance in oil that should be clear

- Excessive foaming when heated

- Thick, sticky residue forming on container surfaces

Smell and Taste Changes

Smell and taste provide reliable indicators of rancidity:

- Rancid oil produces a distinctive unpleasant smell often described as musty, stale, or similar to paint or crayons

- This rancid odor indicates the oxidation process has progressed significantly

- Bad olive oil or expired olive oil frequently develops this characteristic, unpleasant odor

- Fried foods absorb this unpleasant taste, directly affecting customer satisfaction and repeat business

Performance Changes

Performance changes in the fryer signal degradation as well:

- Lower smoke point causes oil to smoke at temperatures it previously handled without issue

- Excessive smoking during normal frying operations

- Foods take longer to cook or cook unevenly

- Fried items appear greasy rather than crisp

Factors That Accelerate Oil Degradation

Several factors speed up the oxidation process, and commercial kitchens encounter most of them daily.

Heat Exposure

Heat accelerates degradation exponentially. High-temperature frying breaks down oil at the molecular level, and repeated heating and cooling cycles compound this stress. Each frying cycle reduces the oil’s remaining useful life. When possible, maintaining a lower temperature appropriate to the food being prepared extends frying oil longevity.

Light and Oxygen Exposure

Light and oxygen trigger oxidation even at room temperature:

- Direct sunlight degrades oil rapidly, breaking down vitamin E and other naturally occurring protective compounds

- Oxygen exposure initiates and sustains the oxidation process continuously

- Storing oil in an airtight container significantly slows degradation

- Clear containers expose oil to more light damage than dark or opaque alternatives

Contamination

Contamination from food particles and moisture accelerates breakdown considerably:

- Food debris left in frying oil provides material for continued chemical reactions

- Water introduced from foods causes oil to spatter and degrade faster

- Salt, seasonings, and breading particles introduced during frying contribute to chemical breakdown and shortened oil life

Improper Storage Conditions

Improper storage reduces shelf life before oil even reaches the fryer:

- Storage near heat sources, such as stoves, ovens, or other hot equipment, shortens usable life

- Humidity promotes degradation

- Storing fresh oil in a dark place away from temperature fluctuations preserves its quality the longest

- Using a smaller bottle for daily use while keeping backup stock sealed reduces overall exposure and waste

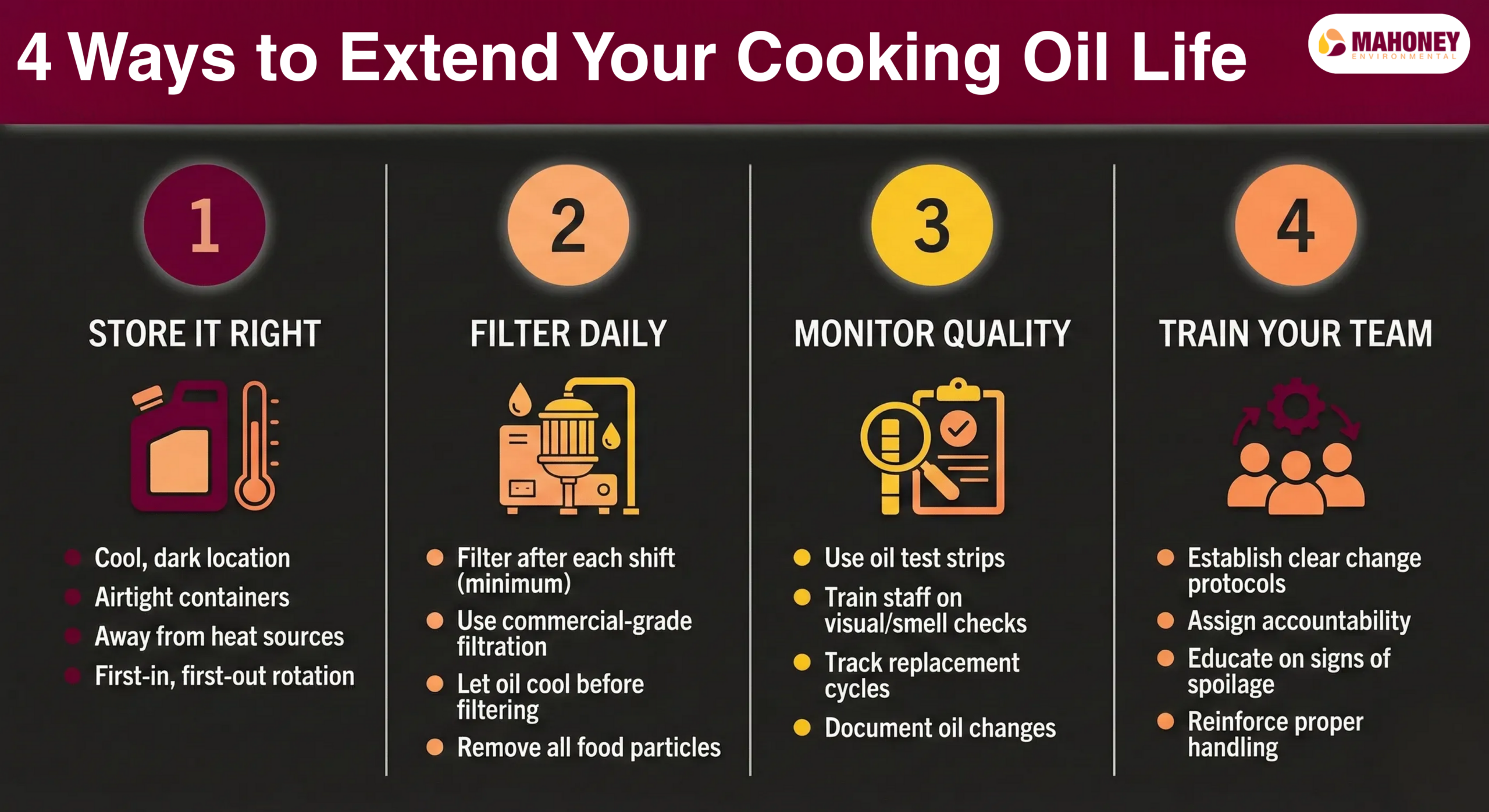

Best Practices for Extending Oil Life in Commercial Kitchens

Implementing consistent oil management practices reduces costs while maintaining food quality.

Proper Storage Protocols

Effective storage begins before oil ever reaches the fryer:

- Store unopened oil in a cool, dark place away from direct sunlight and heat sources

- Keep opened oil in an airtight container to minimize oxygen exposure

- Maintain consistent room temperature in storage areas to prevent expansion and contraction cycles that stress oil

- Rotate stock using first-in, first-out inventory management to ensure older oil gets used before degradation becomes an issue

Filtration Schedules and Techniques

Filtration directly impacts how long frying oil remains usable:

- Filter frying oil daily at minimum, and more frequently during high-volume operations

- Remove food particles that accelerate degradation

- Use filtration equipment rated for commercial use to ensure thorough particle removal

- Allow oil to cool to a safe handling temperature before filtering to protect staff and ensure effective filtration

Monitoring Oil Quality

Regular testing removes guesswork from replacement decisions:

- Use oil quality monitors and test strips for objective measurements that help standardize when to change oil

- Train staff to recognize signs of spoilage through visual inspection and smell checks

- Track oil usage and replacement cycles over time to identify patterns that inform purchasing and operational decisions

- Document oil changes for accountability and consistency across shifts

Staff Training

Training ensures protocols translate into daily practice:

- Ensure all kitchen staff understand proper oil handling procedures and the reasons behind them

- Train team members to identify rancid oil by its unpleasant odor and visual appearance

- Establish clear protocols for when to change frying oil to eliminate confusion and inconsistency

- Assign accountability for oil management tasks to ensure completion

What to Do with Expired or Spent Cooking Oil

Proper disposal of used cooking oil (UCO) matters for compliance, operational efficiency, and environmental responsibility.

Why Proper Disposal Matters

Pouring used cooking oil down drains creates serious problems:

- Fats, oil, and grease (FOG) accumulation in plumbing leads to backups

- Municipal sewer systems actively enforce regulations against FOG discharge

- Violations can result in fines and remediation costs that far exceed proper disposal expenses

- Improper disposal creates environmental contamination that affects water treatment systems and local ecosystems

The Value of UCO Recycling

Used cooking oil is not simply waste, it is a valuable resource when properly collected and processed. Professional recycling programs convert UCO into useful products, turning a disposal obligation into a managed, sustainable process. Foodservice operators benefit from reliable pickup schedules that prevent storage headaches while contributing to environmental goals.

From Waste to Renewable Fuel

Collected UCO is processed into renewable diesel and sustainable aviation fuel (SAF), reducing reliance on petroleum-based fuels. This recycling process keeps harmful compounds out of landfills and water systems while creating products that serve the transportation sector. By participating in UCO recycling, foodservice establishments play a direct role in the renewable fuel supply chain.

Professional Collection Services

Mahoney Environmental provides scheduled UCO pickup tailored to each operation’s volume and production schedule. Our professionals supply appropriate storage containers and maintain collection equipment, ensuring spent oil never becomes a storage burden or compliance concern. With reliable service and transparent processes, foodservice operators can focus on their core business while knowing their used cooking oil is handled responsibly.

Partner with Mahoney Environmental

Cooking oil does expire, and proactive management of oil quality protects food quality, kitchen safety, and operational efficiency. Proper storage extends shelf life, regular monitoring identifies when replacement is needed, and timely changes ensure consistent results. When oil reaches the end of its useful life, responsible recycling through a trusted partner converts waste into renewable resources while keeping operations compliant and efficient.

Contact Mahoney Environmental today to establish a UCO collection schedule designed for your foodservice operation’s specific needs. Our professionals work with you to determine the right pickup frequency, provide appropriate equipment, and ensure your used cooking oil is recycled into products that benefit both your bottom line and the environment.

Call Us Now (800) 892-9392

Call Us Now (800) 892-9392